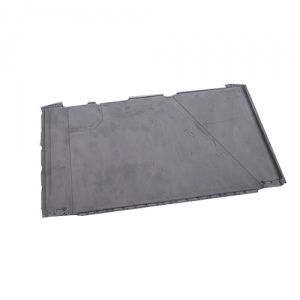

Aluminum alloy die casting

- Product classification:Other parts

- product labeling:Aluminum alloy die casting

- Times of browsing:Already1015Customer focus

The aluminum alloy die-casting material refers to a device device of pure aluminum or aluminum alloy obtained by a casting processing method. Generally, a sand mold or a metal mold is used to pour aluminum or aluminum alloy heated to a liquid state into a cavity, and the obtained aluminum parts or aluminum alloy parts of various shapes and sizes are generally referred to as aluminum die castings.

Modern molding technology for aluminum alloy die casting

The complex aluminum alloy die-casting casting is a new technology of high-quality aluminum castings with the core of electromagnetic pump low-pressure casting technology as the core, aluminum smelting and forming composite purification technology and manufacturing core technology. Electromagnetic pump low-pressure casting metal melt transfer system has a stable flow, flow control is convenient, mitigation process fused alumina back suction and easy to achieve the advantage of the use of process automation, which not only improves the casting quality of aluminum casting casting, but also It can also improve the working environment. Reduce labor intensity and achieve automated and modern casting production.

An important component of purified molten enamel alloy castings is aluminum smelting and compound purification facilities in addition to gas injection and spin foam ceramic filters with high degassing, unless the performance of metal inclusions. In addition, it uses a new long-life lining material with a separate insulation/heating system for large-scale continuous production, as well as intermittent production. This technology has high efficiency, long life, low cost, easy to install, use and flexibility. Casting experience tells us that the quality of aluminum castings to solve complex problems is in three main ways:

(1) Aluminum liquid smelting and melting.

(2) A smooth transitional molten aluminum metal halide lamp.

(3) The size and stability of the mold and sand core process.

Core manufacturing process modeling can have a direct impact on casting quality and yield. Casting porosity, sand sticking, scarring, thermal cracking and surface quality, dimensional accuracy, and the relationship between sand properties are very good. The new technology for modeling and manufacturing is the PEPSET core resin binder for the original zircon sand sand resin from hard sand, the difficult self-hardening sand mechanism for an independent, non-hardening chemical reaction. Initially, it is time to start hardening and curing. Once the reaction starts fast. So the coach bag, because in a small, hard, high-strength, fat gas collapse, has good performance is the complexity of the casting surface, ensuring dimensional accuracy of quality and stability.

Previous page:Surveillance camera accessories

next page:Magnesium alloy die casting